Performance

Experience the unmatched performance of Kitamura machining centers. Get high-efficiency cutting with Kitamura’s gear-driven spindles. Achiever stable and precise machining with an efficient oil chiller system. Benefit from the world’s fastest spindles and high-speed rapid feed development. Enhance productivity with efficient workpiece handling systems. Choose Kitamura for advanced machining solutions.

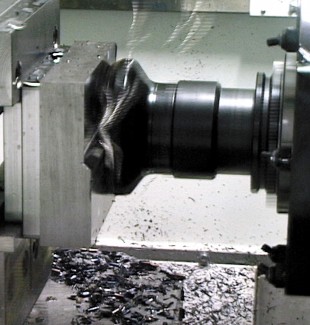

Multi-Step, Gear Driven Spindles

- Delivers high-efficiency cutting performance with low energy consumption

- No influences from characteristics of the motor.

- Efficient oil chiller system minimizes thermal displacement and maximizes spindle life to achieve the performance needed in high accuracy machining.

- Less motor heat means tighter bearing pre-load. This equals a stiffer and more stable spindle for excellence in cutting performance.

Focus on Productivity – Kitamura’s Gear Driven Spindle Development

- 1992 – Kitamura first introduces #40, 10,000min-1, 2-Step Gear Driven Spindle

- 1997 – Kitamura first introduces #50, 10,000min-1, 2-Step Gear Driven Spindle

- 1998 – Kitamura first introduces #40, 15,000min-1, 2-Step Gear Driven Spindle

- 2002~ Current – Never before seen #40, 20,000min-1 and #50, 12,000min-1, 4-Step Gear Driven Spindles. WORLD’S FASTEST!

Focus on Technology – High Speed Rapid Feed Development on Solid Box Ways

- 1991 – 24m/min (945ipm) rapid feeds on SOLID BOX WAYS

- 1995 – 30m/min (1,181ipm) rapid feeds on SOLID BOX WAYS

- 1999 – 50m/min (1,969ipm) rapid feeds on SOLID BOX WAYS

- 2014~ Current – 60m/min (2,362ipm) rapid feeds on SOLID BOX WAYS. WORLD’S FASTEST!

Efficiency-Enhancing, Workpiece Handling Systems

- Kitamura’s multi-pallet systems offer savings on set-up time, manpower and tooling costs. Unique design features allow for these systems to be installed on existing machines in the field, allowing for standard machine usage and eliminating extended delivery times

- Flexible Manufacturing Systems are tailored to each individual customer’s manufacturing requirements and come in a variety of types and sizes to fit any type of machining application. Easily expandable, these systems allow for the addition of systems, cells, machines and loading stations further promoting and unmanned machining development process for even the smaller sized job shops

- Kitamura’s patented high-speed “Fixed-Pot” ATC system ensures accurate and effective tool changes and tool identification. Multi-tasking minimizes the “out-of-cut” time, returning the old tool and placing the next tool in the ready position while the tool in the spindle is still cutting the work piece.

- Patented “Fixed-Pot” tool magazine systems are expandable in the field (up to 300T on our HMC models) increasing machining uptime and allow for growth as you cultivate your lights-out business