Easy-to-Use CNC Control with Redesigned Graphical Interface

April, 2023

Kitamura’s high-performance Arumatik-Mi control system has been updated with a redesigned graphical interface, making it easier than ever to use for operators of all levels. The intuitive design and user-friendly features of the Arumatik-Mi make it a top choice for easier programming and part set-up and simplified machine operation.

Download PDF

MedCenter5AX - Simultaneous 5-Axis, Ultra Compact VMC

August, 2019

Kitamura expands it's 5-axis line up with this ultra-compact 5-axis VMC, offering the largest work envelope in its class. This high speed machining center offers unparalleled precision, accuracy and speed for expanded machining capability in the machining of highly complex, multi-sided parts in one set-up.

Download PDF

Ultra Compact Footprint HMC for the Automotive Industry

January 2019

Manufactured in Japan with ultra-high speed rapids of 2,362ipm, the Mycenter-HX250iG offers high efficiency with the ability to mill, bore, drill, tape and thread light to heavy duty materials on a single machine with the flexibility to expand tools and pallets in the field as needs grow.

Download PDF

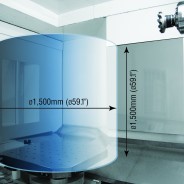

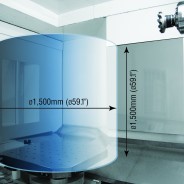

Kitamura Introduces the Mycenter-HX500iG/630

July 2018

The Mycenter-HX500iG/630 is designed specifically for manufacturers and job shops that need to produce close tolerance parts from the toughest of materials, providing both the high precision and high volume manufacturing capabilities needed for larger parts production in the aerospace, automotive, energy manufacturing, heavy construction and similar medium to large part machining industries.

Download PDF

A Watch Maker and His Kitamura HMC

January 2018

When this customer decided it was time to step up his game, there was no doubt that a new Kitamura was in his future. A small scale, #30 taper, high speed HMC that could handle grade 5 Titanium. The answer was the Mycenter-HX250iG

Download PDF

Kitamura Introduces IoT Platform Partnership

September 2017

Kitamura's Anywhere-Remote® mobile notification and machine monitoring suite includes E-mail status updates, machine monitoring software suites that range from basic plug and play packages to those that are customized to suite each individual customer's application and MTConnect® ready adaptor (basic) allowing for machines to be readily and easily adapted to end users already running their own in house machine monitoring software protocols.

Download PDF

Kitamura's all NEW high speed, compact #40 HMC - Mycenter-HX300iG

March 2017

Kitamura's ultra compact HMC reduces floor space by 20% when compared with our 400mm horizontal without sacrificing speed, power, accuracy or reliability.

Download PDF

Kitamura 5-Axis VMC Makes This a "One Stop" Shop

February 2017

Anaheim Precision Manufacturing services high tech aerospace and commercial customers on the West Coast. Needing something that could handle heavier materials and tighter tolerances, they turned to Kitamura Mytrunnion-4G 5-Axis Vertical Machining Centers. The result? Flawless finishes and mind blowing repeatability.

Download PDF

World's Fastest Horizontal Machining Technology

March 2016

Kitamura's Mycenter-HX400G - Updated and upgraded. Increase productivity with new features, feeds and speeds!

Download PDF

NEW Breakthrough in VMC Machining - Kitamura Mycenter-3XD

January, 2015

Kitamura introduces their newest Vertical Machining Center. The Mycenter-3XD is a high output, compact work horse with 35HP of unbelievable cutting capability. Did we mention the extremely affordable price point?

Download PDF

Racing Toward More Parts Per Pallet Load

May, 2015

Kitamura's Horizontal Machining Centers provide this worldwide supplier of high-end motorsports components the optimized workflow necessary to increase their production of pistons and connecting rods for the racing industry.

Download PDF

A Winning Strategy for Efficient Machining of Inconel

May, 2015

Kitamura Horizontal Machining Centers take center stage at this Employee engaging Tacoma Machine Shop ripping through the hardest and most challenging of materials leaving in their wake more profitable parts of good quality faster without slowing down the rhythm of the shop.

Download PDF

Reducing Set-Ups with Automated Pallet Systems

November, 2014

Wouldn't it be great to have the ability to set-up a pallet once and then be done with it? Kitamura automated pallet systems help this California Job Shop recover time lost to repeat set-ups for recurring part orders.

Download PDF

No Compromises for Large-Mold Machining

December, 2014

Kitamura's Double Column Machining Centers expand the range of work being processed and offer additional design freedom for larger molds for this Wisconsin Operation.

Download PDF

Small Complex Component Machining

June, 2014

Superior surface finishes, a reduction in cycle times and high level accuracies for this New England job shop results in parts as close to perfect as possible - Courtesy of Kitamura.

Download PDF

Machining Titanium with a Space Saving VMC and 5-Axis Retrofit Increases Metal Removal

February, 2013

A small shop added two new machines, each of which is more advanced than any of the previous machine tools the company has used, and one of them is a KITAMURA. Read on to share in the shops experiences and how high quality equipment makes an impact.

Download PDF

Kitamura Mytrunnion-4G - Kitamura Expands on it's 5-Axis VMC Line Up!

September, 2014

The Mytrunnion-4G 5-Axis VMC has been designed specifically for manufacturers and job shops that require higher levels of flexibility and versatility in the materials that they machine at an incredibly affordable price point.

Download PDF

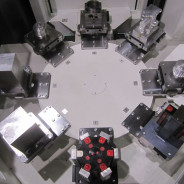

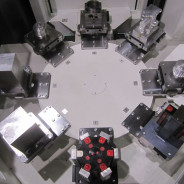

Invest in Automation - Go Horizontal with Multi Pallets and Tools to Increase Productivity

September, 2014

Components of varying shapes and sizes cause one manufacturer to rethink their production techniques. With the addition of Kitamura's Mycenter-HX400G Horizontal Machining Center with an 8-station automatic pallet changer, this Brea, CA manufacturer can now have as many as 20 parts set up and ready to go at one time. Most of the shops parts can now be machines in one operation, relieving the pressure.

Download PDF

Kitamura's Heavy Duty Mycenter-HX800iLTGA for Precision Custom Component Machining

August, 2013

Large Part Machining - Kitamura's Mycenter-HX800iLTGA updates outdated equipment and offers this Ohio user improvements in speed, efficiency, precision and rigidity for their heavy duty machining requirements.

Download PDF